|

SETTING THE CARBURETOR FLOAT

HEIGHTS IN A FERRARI 308

By The Birdman

This is easy and can be done by anyone in about

3-4 hours, including removing the airbox.

WHY DO IT?

The floats in your carbs are very simple devices. They are

just like the float/valve in a toilet that shuts the water

off when the level is high enough. In the toilet, if your

float valve didn't eventually shut off the water, the level

would rise until it overflowed onto the floor. Likewise, if

the float shut the water off too soon, it wouldn't be high

enough for a proper flush and nobody wants that!

The float/float valve in the carburettor does the same

thing. It controls the level of fuel in the float bowl. Too

much or too little and the car will not run right because

fuel will not flow as designed.

Before you begin, you need a carb rebuild kit. I got mine

on eBay for about $60 (enough to rebuild all 4 carbs). You

don't actually need the entire rebuild kit, but you do want

to replace the gaskets under the carb tops before you put

them together. While you have the tops off, you might as

well replace the float valves too. Both of these items come

in the rebuild kit.

The first step is to remove the airbox so you are looking

down on all 4 carbs. This has been covered elsewhere,

so I don't think you need a run down on this. (Basics:

Remove the filter element, unscrew the (16) 8mm nuts, pull

the trumpets off, and then remove the airbox, being careful

to unhook the breather hose on the underside).

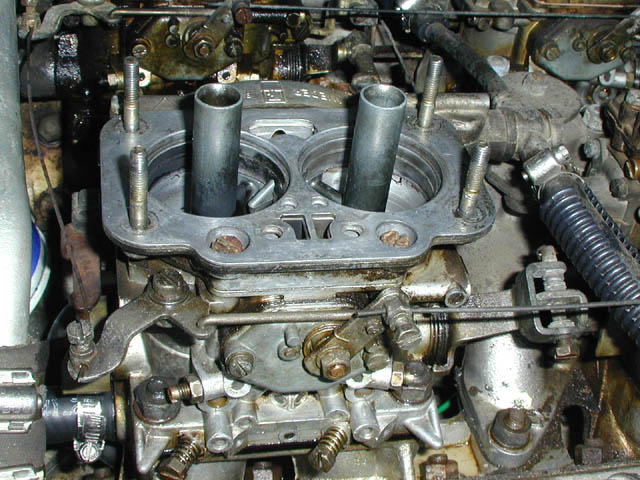

Now you are looking at 4 beautiul Webers in all their

glory. If they look like mine, they are dirty. If they are

clean, you need to drive your car more.

|

|

|

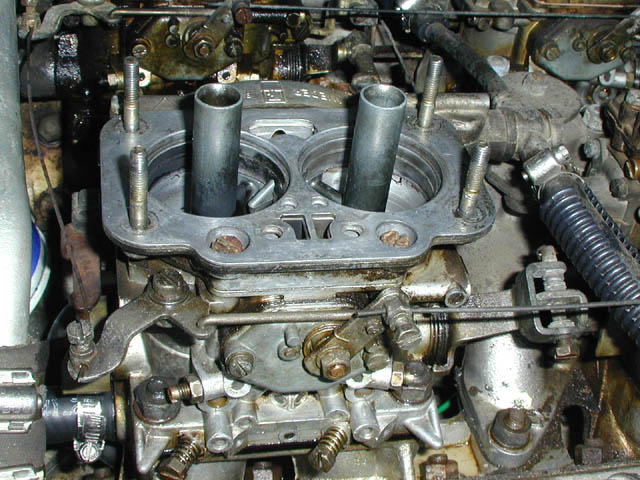

Here is your typical dirty carb with the airbox

removed.

|

|

|

|

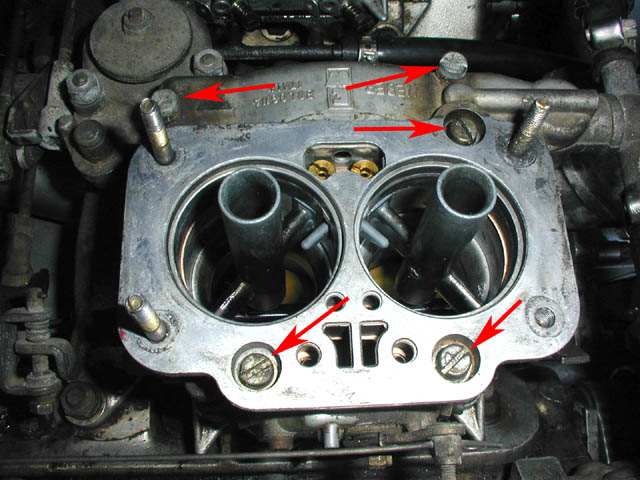

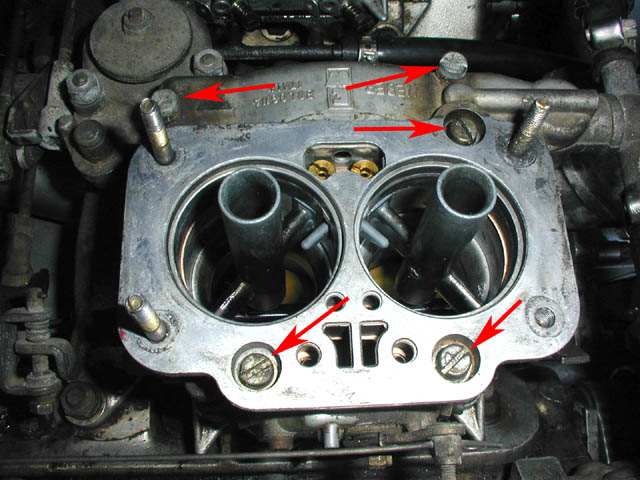

Next, here is a shot of the 5 screws you need to

remove. What you are about to do is remove the top

of the carb. The top comes off, complete with the

float assembly. It does not require that you mess

at all with the linkages connecting all the carbs.

Nothing will get messed up doing this.

First remove the fuel lines to this particular

carb.

Next, take out the 5 screws.

Finally, just lift the top off. Be gentle with

the float.

|

|

|

|

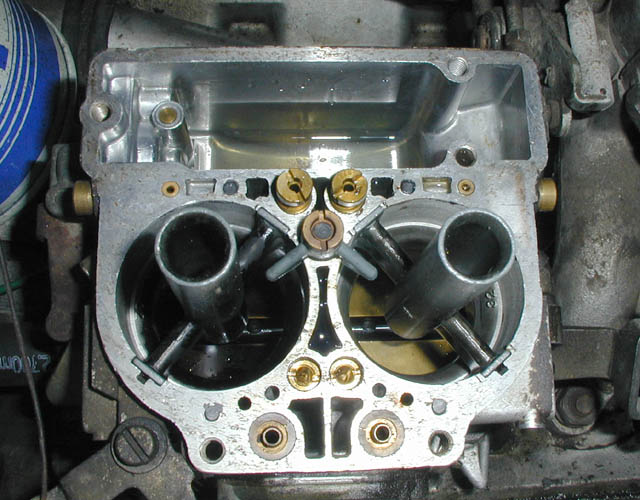

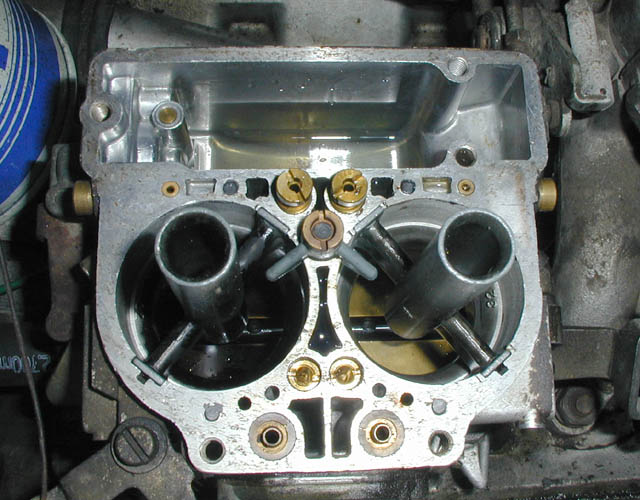

Here is what the carb top looks like. The float

is hanging down from a pivot.

|

|

|

|

Looking down into the carb (gasket removed) you

can see the two throats (note that the left one is

discolored from the engine "coughing" back through

the carb...a common sign of running lean).

At the back, you can see the reservoir of fuel

controlled by the float height.

|

|

|

|

Here is a close up of the float valve. What you

have is a little plunger with a cone-shaped point

resting in a seat. The seat is the part with the

hex head on it. The plunger is the part with the

round top being pushed on by the tab on the

float.

If you wish to replace the valve, you need to

remove the float. Just push the pin that holds the

float out. (In this picture, you would push the pin

out away from you). Once the float is free, you can

shake it to be sure that is hasn't leaked and

allowed fuel inside. If it has, it's toast and must

be repaired or replaced. Next, use a 10 mm box end

wrench to unscrew the valve seat and replace with a

new one, plus a new sealing crush washer. The

washer is important to not only seal it but provide

the right clearances, so you need it.

Once it's back together you can adjust the

height. (next step)

|

|

|

|

To measure the float height, you must hold it

vertically as shown, so that the float tab is

resting LIGHTLY against the plunger of the valve.

You will see that when you hold it vertically, the

tab rests lightly, but if you hold it upside down,

for example, the weight of the float depresses the

plunger and throws the measurement off.

|

|

|

|

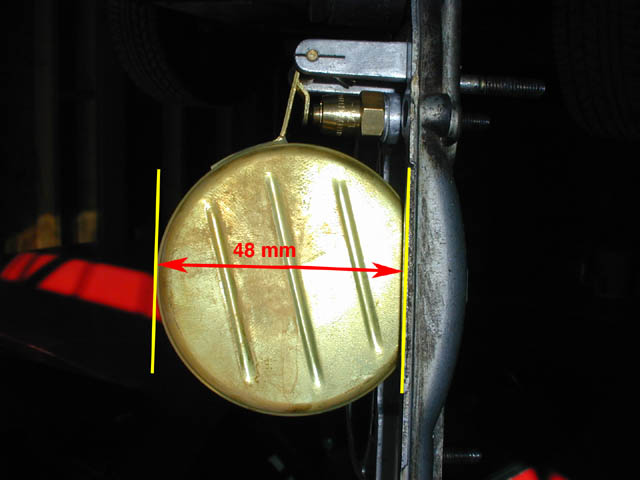

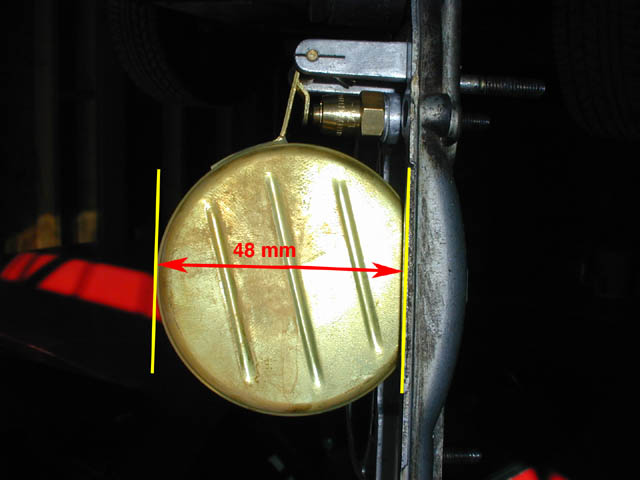

With the unit held vertically, use a clear ruler

marked in mm (available at your local stationary

supply place) to measure from the bottom of the

float to the bottom edge of the carb top, as shown.

(Much easier to use a clear ruler than an opaque

one!) Be sure to measure without the

gasket.

It should be 48 mm. If it is not 48 mm, bend the

tab that presses against the plunger until the

measurement is right. Bear in mind that minute

changes in the tab make a much larger difference in

the float height.

|

|

|

|

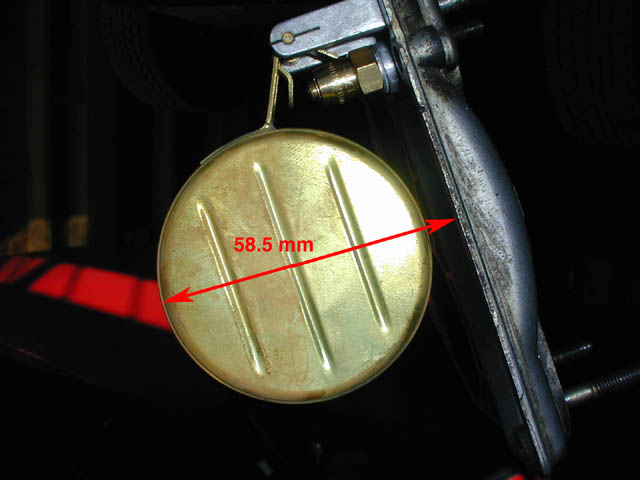

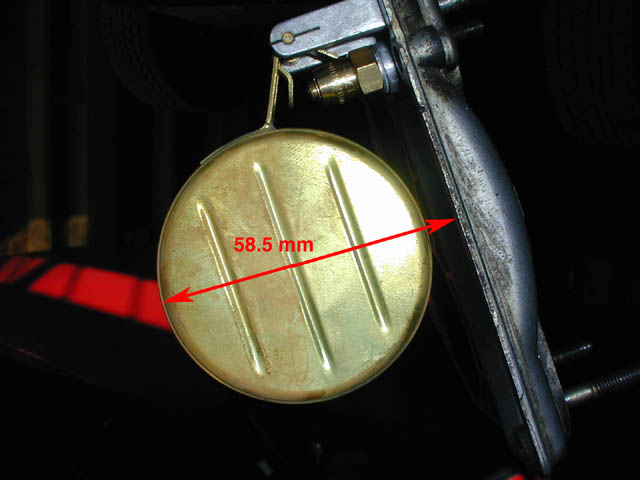

Now hold the carb top so that the float hangs

down. At this point it is resting on a second tab,

pressing against the side of the valve seat. This

tab just keeps the float from hanging too low and

hitting the bottom of the carb. This tab should be

adjusted so that the measurement is 58.5 mm. That

gives it a travel of 10.5 mm from top to bottom.

Don't ask me how they decided to use 58.5 mm

instead of a nice round number like 58, and GOOD

LUCK getting it exactly 58.5. I'm sure that

anywhere from 58 to 59 is fine.

|

That's it! Your float is now adjusted. Replace the gasket

on the carb top, and gently put the top back on the carb,

being careful not to bend the float, and screw it back down.

Now move on to the next carb.

A few helpful hints: when you remove a carb top, there

will be fuel in the passages and valve. You might want to

take it outside and give it a gentle squirt of air to blow

the fuel out so it doesn't drip all over the garage.

Wearing nitrile gloves will keep you from smelling like a

gas station attendant when you are done.

Be careful how you lay the fuel lines when you unplug

them as they will drip too. You don't need them dripping on

anything important like plug wires.

When you are finished with the entire job and have

replaced the carb tops, run the fuel pump and look down the

throats of the carbs to be sure that the valves are working

and fuel is not overflowing into the engine. That is

BAD.

Happy adjusting!

<--BACK to Main

Page

THE FINE PRINT: This service procedure is

provided as the personal experience of the author who is in

no way an expert, so take this advice with what you

paid for it. I am not liable if you blow yourself

up!

|